Vacuum chambers are widely used in many scientific and industrial processes, including electronics manufacturing, material research, and space simulations. These chambers provide a controlled environment by removing air and other gases, allowing sensitive experiments or manufacturing steps to take place without contamination or interference. Automation inside vacuum chambers is essential to improve efficiency, precision, and safety. One key component that enables this automation is the linear vacuum feedthrough.

Understanding Linear Vacuum Feedthroughs

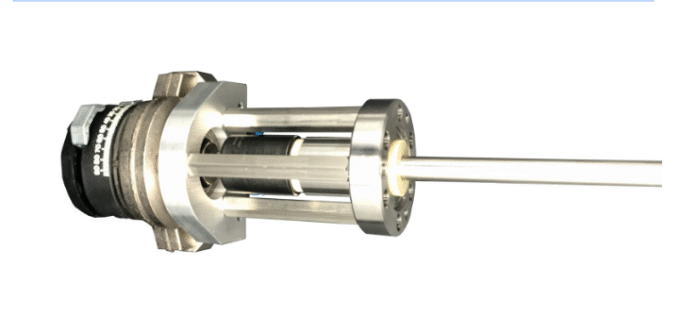

A linear vacuum feedthrough is a specialized mechanical device designed to transmit linear motion from outside a vacuum chamber into its sealed interior without breaking the vacuum. In simple terms, it acts like a moving arm or rod that can slide in and out of the vacuum chamber, allowing machines or tools inside to move precisely while maintaining the airtight environment.

The feedthrough has to be carefully engineered to prevent any air leaks, which could ruin the vacuum conditions. It also needs to withstand the pressure difference between the outside atmosphere and the vacuum inside the chamber. The design typically includes seals, bearings, and sometimes bellows that allow smooth, controlled motion.

The Role of Linear Vacuum Feedthroughs in Automation

Automation inside vacuum chambers often involves moving parts, such as robotic arms, probes, or sample holders, which need to be controlled remotely. Linear vacuum feedthroughs provide the crucial mechanical link to make this possible. They allow automated equipment outside the chamber to push, pull, or slide components inside the chamber with great accuracy.

Without these feedthroughs, any adjustment or movement inside the vacuum would require breaking the vacuum seal, causing delays and potential contamination. By enabling continuous movement without compromising the vacuum, linear vacuum feedthroughs help automate processes more efficiently.

Enhancing Precision and Repeatability

One major advantage of using linear vacuum feedthroughs in automated vacuum systems is improved precision. Many applications require exact positioning of parts or instruments inside the chamber, sometimes with micrometer-level accuracy. Linear vacuum feedthroughs are designed to offer smooth and controlled motion, which means automated systems can perform delicate tasks with high repeatability.

For example, in semiconductor manufacturing or thin-film deposition, precise positioning can impact the quality and consistency of the final product. The ability of linear vacuum feedthroughs to move components steadily and accurately makes them invaluable in these sensitive processes.

Increasing Efficiency and Productivity

Automation powered by linear vacuum feedthroughs allows operations to be faster and less dependent on manual intervention. Machines can handle repetitive tasks, adjust positions, or conduct experiments continuously without stopping to re-establish the vacuum. This leads to shorter cycle times and higher productivity.

In addition, by reducing the need for human access inside vacuum chambers, these feedthroughs help maintain a cleaner environment, lowering the risk of contamination and equipment damage. As a result, industries benefit from better yield and lower operational costs.

Improving Safety in Vacuum Environments

Vacuum chambers can pose safety risks when manual access is required, such as exposure to hazardous materials or sudden pressure changes. By incorporating linear vacuum feedthroughs into automated systems, operators can control equipment remotely, minimizing physical interaction with the chamber.

This remote control enhances worker safety while also protecting delicate components inside the chamber from accidental damage. The reliability and durability of well-made linear vacuum feedthroughs ensure that automation can proceed smoothly without unexpected breakdowns.

Versatility Across Various Applications

Linear vacuum feedthroughs are used in a broad range of fields, including scientific research, manufacturing, aerospace, and electronics. Their ability to maintain a vacuum seal while allowing linear motion makes them a fundamental part of many automated vacuum systems.

Whether it is moving a probe inside a research vacuum chamber or adjusting parts in a coating process, linear vacuum feedthroughs provide the necessary mechanical functionality to achieve automation goals across different industries.

Conclusion

In summary, linear vacuum feedthroughs play a critical role in improving automation within vacuum chambers. By enabling precise, efficient, and safe linear motion without compromising the vacuum environment, these devices enhance productivity and accuracy in many industrial and scientific applications.

As technology advances and the demand for automated vacuum processes grows, the importance of reliable linear vacuum feedthroughs will only increase. Understanding their function and benefits helps industries make informed decisions when designing automated vacuum systems.